Are you ready to venture into the world of thermal imaging like never before?

To uncover secrets hidden in plain sight and reveal a new dimension of our environment?

Well, buckle up because we are about to dive into the scintillating world of thermal drones and sensors for drone inspections!

These cutting-edge devices have revolutionized the inspection process across numerous industries, providing crucial information that would have been otherwise impossible to obtain.

So, join us as we embark on this enlightening journey, exploring the transformative power of this innovative technology and how it enables us to see the world differently.

Hold on tight because we’re about to take you through one of the most thrilling rides in aerial inspection innovation!

- Introduction to Thermal Imaging Drones

- What is a Thermal Camera?

- How Thermal Imaging Works

- Advantages of Using Thermal Drone Cameras

- Drone-Based Thermal Imaging Applications

- Some top Thermal Imaging Sensors available in the market today

- Some top Thermal Imaging Drone Solutions available in the market today

- Which software do you need to manage your Thermal Imaging data?

- How can you get started leveraging Thermal Imaging Drones in your business?

- Our experience with Professional Thermal Reporting Software for FLIR Cameras

Introduction to Thermal Imaging Drones

The advent of modern thermal imaging technology is revolutionizing the way we see the world from an aerial perspective.

Particularly, it has opened up new possibilities and applications for drones equipped with thermal sensors.

As drone technology has evolved, integrating thermal imaging capabilities has considerably increased the scope of their utility.

A few key points that describe the significance and impact of thermal imaging drones:

- Thermal cameras were initially developed for military applications like night vision, targeting enemies, and navigating through smoke-filled battlefields.

- Integration of drone technology with thermal cameras has greatly expanded their reach and application in various industries, including security, agriculture, and inspection.

- FLIR Systems, DJI, Parrot, Yuneec, and Autel Robotics are some of the major companies that have pioneered the development of thermal imaging drones, making them accessible to diverse users.

- From detecting subtle temperature differences in structures to locating faults in power lines and monitoring oil and gas facilities, thermal imaging drones are highly efficient and time-saving tools for various industries.

- One significant use of thermal imaging drones is inspecting energy-efficient buildings, detecting leaks or water damage, and thermal surveys, hence contributing toward a more sustainable future.

Overall, thermal imaging drones have vastly expanded the potential applications of drone technology, offering innovative solutions for numerous industries and fueling our imaginations to explore new possibilities in the future.

The integration of thermal cameras into drone technology has expanded the use of prosumer drones and brought thermal imaging to new heights — both literally and figuratively.”

Technology Executive

What is a Thermal Camera?

A thermal camera is an advanced imaging device that captures and displays varying temperatures in objects and materials in real-time using infrared radiation.

Here is some background you need to know about thermal cameras.

All objects emit infrared radiation, which is proportional to their thermal energy.

Unlike visible light, infrared radiation cannot be seen by the human eye.

Thermal cameras are equipped with a sensor and a lens that focus on infrared radiation instead of visible light, allowing them to detect even minuscule temperature differences as small as 0.01℃.

The software within the camera processes the infrared data and using color representation presents it as a visual thermal image, where hot spots typically appear in bright yellow or white.

In contrast, colder spots are shown in deep blue or violet.

Thermal cameras were initially developed for military use to detect enemies at night or on smoky battlefields.

Today, they have been adapted into handheld and mountable devices for a wide range of applications, including inspections, surveillance, maintenance, and safety.

Further, as drone technology continues to evolve, thermal cameras have been integrated with unmanned aerial vehicles (UAVs) to increase the efficiency of thermal imaging in various professional sectors.

As a result, thermal cameras play a crucial role in numerous industries, providing valuable insights and enabling quick, accurate decision-making.

How Thermal Imaging Works

Thermal imaging is a highly advanced technology that has revolutionized various industries and professions by allowing the visualization of temperature differences in objects and environments.

Here’s a quick overview of how it works.

- Thermal imaging cameras capture images by detecting infrared radiation (heat) emitted by objects. This radiation is picked up by the camera’s sensitive heat sensors, which are attuned to wavelengths ranging from approximately 1000 nanometers to about 14,000 nanometers.

- These cameras create thermograms or thermal images, which display the spatial distribution of temperature variations in the captured scene. Color schemes like blue-to-red are commonly used, where blue represents colder zones, and red indicates hot zones.

- Isotherms can be set on thermal drone control panels, customizing temperature settings and making it easier for users to identify high-temperature zones.

- With advanced thermal imaging software, users have access to features like real-time heat updates and temperature tracking for specific objects.

- Thermal imaging makes it possible to perceive one’s environment even if there is insufficient lighting, thanks to its ability to detect the infrared radiation emitted by all objects with a temperature above absolute zero. This makes it an effective form of night vision technology.

Overall, thermal imaging technology has significantly improved the efficiency and safety of various inspections, such as in cell towers, wind turbines, and infrastructure maintenance.

By integrating thermal imaging cameras with commercial drones, these tasks can be performed more accurately and quickly while reducing potential risks for inspectors.

Advantages of Using Thermal Drone Cameras

Thermal drone cameras have revolutionized various industries and applications, providing numerous advantages over traditional methods of thermal inspection.

What are the key benefits and advantages?

Increased Efficiency: Thermal drone cameras allow for faster and more efficient inspections, reducing the time and effort required to cover large areas, and providing accurate and precise data in real-time.

“Using the thermography drone, we can provide our customers with inspection services for large buildings and photovoltaic systems which were not previously possible.”

Enhanced Safety: By using thermal drone cameras for inspections, operators can maintain a safe distance from hazardous situations, such as electrical facilities, fires, and gas leaks. This minimizes the risk to personnel, ensuring greater safety for workers involved in the inspection process.

“Drones equipped with thermal sensors become a powerful tool. They can maneuver difficult environments like tall roofs and large industrial sites to detect hot and cold spots and collect exact temperature data, all while keeping pilots at a comfortable and safe distance from the action.”

Cost-Effectiveness: Compared to traditional methods of thermal imaging, drones significantly reduce the costs associated with equipment, manpower, and time. Their ability to quickly inspect large areas and hard-to-reach locations provides more accurate and reliable data, reducing the need for expensive follow-up inspections.

Thermal drone cameras offer significant advantages in terms of efficiency, safety, and cost-effectiveness.

These cutting-edge devices are reshaping the way industries conduct inspections, providing valuable data, and promoting a safer work environment for operators and personnel.

Drone-Based Thermal Imaging Applications

Thermal imaging technology has revolutionized various industries, from agriculture to search and rescue operations.

Drone-based thermal imaging has emerged as a game-changer, providing unique solutions for a variety of applications.

Roof and Building Inspections

The integration of thermal imaging sensors into drone technology has revolutionized the way roof and building inspections are conducted.

Here’s how thermal imaging drones are transforming the roof and building inspection space.

Quick and Comprehensive Inspections:

Drones equipped with thermal sensors can cover large areas within a short amount of time, significantly reducing the duration of inspections compared to traditional manual methods.

This enables professionals to detect potential issues at an early stage, promoting timely repairs and cost savings.

Enhanced Accuracy:

By capturing high-resolution thermal images of rooftops and building exteriors, drones provide valuable data that allows for the identification of temperature variations caused by leaks, energy inefficiencies, and structural damage.

This information aids in the prioritization of repair and maintenance efforts, ensuring the longevity and safety of the structures.

Reduction in Risks and Expenses:

Utilizing drones for inspections eliminates the need for scaffolding, ladders, and other expensive equipment, reducing both labor costs and the risks associated with manual inspections.

This makes drone-based thermal imaging a safer, more cost-effective choice for both residential and commercial property owners.

“Drones with thermal sensors provide a reliable and efficient solution for detecting leaks in rooftops. They enhance the accuracy and speed of inspections enabling early identification of problem areas and facilitating timely repairs.”

Thermal imaging drones have revolutionized roof and building inspections, offering a safer, more accurate, and cost-effective approach to maintaining the integrity of our structures.

Sounds like a recurring theme? Right?

It is, and that’s why Thermal Imaging is reshaping so many applications.

Solar Field Inspections

Solar Field Inspections play a vital role in the photovoltaic industry as they ensure the efficient functioning of solar farms and identify any potential faults or issues.

With the growth of the solar farm industry, the demand for drone-assisted solar inspections has seen a significant increase.

You know the benefits by now.

Key aspects of solar field inspections include:

The drone plays a crucial role in carrying the thermal and visual color (RGB) cameras during the inspection, with industrial-grade multi-rotor drones such as the Matrice 200 series being commonly used.

Drones equipped with thermal cameras can quickly identify heat anomalies, pinpointing possible faults in a fraction of the time it takes for manual inspections by technicians.

Software applications are essential for processing the data collected by thermal cameras during solar inspections, ensuring that identified issues can be promptly addressed.

Solar field inspections help in maintaining the solar farms’ assets, through improved preventive maintenance programs, leading to a significant impact on overall profitability.

As the solar farm industry continues to grow, professionals must understand the available software tools and utilize the best-suited drone software for their solar inspection business.

We don’t see a better alternative at this point for inspecting soalr panels and farms accurately, cost-effectively, safely and timely.

Electrical Inspections

Integrating thermal cameras with drones has revolutionized electrical inspections.

They allow for the monitoring and examination of electrical facilities, such as substations, power lines, and power distribution systems, from a safe distance without the need for expensive equipment or the risk to human lives.

By employing drones for electrical inspections, the number of engineers on-site is significantly reduced, with only a few drone pilots and flight controllers necessary for the operation.

This translates to a reduction in both time and expense.

Drones equipped with thermal cameras can easily navigate and provide crucial information even in difficult-to-reach locations.

Thermal imaging enables the detection of overheating spots, damaged components, and faulty connections within electrical systems, facilitating timely maintenance and preventing potential hazards.

As technology continues to evolve, the use of thermal imaging drones in electrical inspections will undoubtedly become even more efficient and indispensable.

Oil and Gas Applications

Oil and gas applications have seen a significant rise in the utilization of thermal drone cameras, with drones playing a vital role in enhancing efficiency, safety, and cost-effectiveness.

Key benefits and applications of thermal drone cameras in the oil and gas sector include:

- Leak detection: Thermal drone cameras can easily detect gas leaks and temperature anomalies in pipelines and facilities, ensuring early identification and minimizing potential damage and environmental impact.

- Monitoring remote areas: Advanced drone technology, such as solar-powered and hydrogen fuel cell-powered drones, enables continuous and prolonged monitoring of remote and hard-to-reach locations in the oil and gas industry.

- Efficient data gathering and analysis: Equipped with various sensors, thermal drone cameras can collect and transmit information to a central hub where AI-powered analysis can draw insights and predictions related to defects, corrosion, and maintenance schedules.

“Thermal cameras equipped with optical gas imaging sensors can spot methane and other gases during the pipeline inspection.”

Yes, here, too, the benefits are substantial. For a more detailed discussion of drones and sensors, you should read our piece on optical gas imaging drones in oil fields.

Tower and Power Line Inspection

The electrical power industry has heavily benefitted from the integration of drone technology, especially when it comes to tower and power line inspections.

Drones equipped with thermal imaging cameras provide a highly efficient and safe solution for inspecting assets, which was once a time-consuming and risky process that often involved manual labor and expensive equipment.

Drones minimize the risks associated with working at height and in close proximity to high-voltage power lines.

They eliminate the need for climbing towers or using bucket trucks to perform inspections, ensuring a safer working environment for inspectors.

Drones can cover vast distances in a relatively short amount of time, making the inspection process quicker and more cost-effective.

The high-quality imagery captured by drones also reduces the need for multiple inspections and potential downtime.

Equipped with advanced thermal imaging cameras, drones can detect potential issues like overheating spots, damaged components, and faulty connections.

The high-resolution imagery produced by drones enables inspectors to assess the condition of assets and detect even the smallest anomaly effectively.

Drones can easily maneuver around tall towers, power lines, and other challenging terrains, providing unobstructed views from multiple angles that might not be easily accessible for human inspectors.

There is no doubt drone technology has revolutionized the way tower and power line inspections are conducted, ensuring a more efficient and safe approach to essential maintenance procedures.

“In terms of safety, scalability, and the ability to collect detailed data, drones offer significant benefits for the inspection of electric transmission and distribution infrastructure.”

Many other Industrial Applications

Here are some other major applications of drone-based thermal imaging:

- Wildlife Monitoring: With thermal imaging’s ability to detect heat signatures, researchers in Denmark have successfully used drones equipped with thermal cameras to estimate population counts of European Hares (Lepus europaeus) across the country.

- Navigation: In GPS-denied areas, drone-based thermal sensors provide real-time information about the surrounding environment, offering reliable navigation even when traditional sensors are ineffective.

- Search and Rescue: Drone-based thermal imaging can aid in search and rescue missions, identifying heat signatures of missing people day or night while avoiding potential dangers ground-based rescuers face.

- Crop Monitoring: For agriculture purposes, thermal imaging can be utilized in monitoring water management and identifying issues related to irrigation systems, enabling more efficient farming practices.

- Infrastructure Inspection: Drone-based thermal imaging assists in roof inspection and solar panel inspection in identifying structural defects and underlying problems invisible to the naked eye without manual inspection.

Drone-based thermal imaging not only opens new possibilities for existing applications but also has the potential to inspire innovative solutions for future challenges.

Some top Thermal Imaging Sensors available in the market today

Some of the top Thermal Imaging Sensors available in the market today include:

| Model Name | Type | Manufacturer | Link | Description | Specifications | Price |

|---|---|---|---|---|---|---|

| Zenmuse H20N | Sensor | DJI | Link | A versatile hybrid payload that rises to the occasion. It is designed for night vision and has an IP44 rating, making it suitable for various weather conditions. | Infrared Zoom: Dual Thermal Cameras with Resolution: 640×512, 2x Zoom (Equivalent Focal Length: 53 mm), 8x Zoom (Equivalent Focal Length: 196 mm), Night Vision Wide Camera: Starlight Sensor: 2MP, Night Vision Zoom Camera: Starlight Sensor: 4MP, 20× Optical Zoom, 128× Max Zoom, Laser Rangefinder: Range: 3 m to 1200 m, Accuracy: ± (0.2 m + D×0.15%) | Contact Manufacturer |

| Zenmuse XT2 | Sensor | Teledyne FLIR | Link | A dual-sensor thermal imaging solution designed for commercial drones. | Resolution: up to 640×512, Range: N/A, Weight: 629 g, Compatibility: Matrice 200 Series, Matrice 600 Series | Contact Manufacturer |

| Vue TZ20-R | Sensor | FLIR | Link | A high-resolution, radiometric gimbaled thermal zoom drone payload made in the USA. It enables DJI V2 Matrice 200 series and 300 pilots to see and measure thermal details, increasing the value and extending the lifetime of their drone fleet. | Resolution: 640×512, Range: N/A, Weight: N/A, Compatibility: DJI V2 Matrice 200-series and Matrice 300 | Contact Manufacturer |

| FLIR Vue Pro R | Sensor | FLIR | Link | A thermal measurement instrument and data recorder that adds tremendous value to your sUAS operations and services. | Resolution: 640×512, Range: N/A, Weight: N/A, Compatibility: DJI V2 Matrice 200-series and Matrice 300 | Contact Manufacturer |

| Vue Pro | Sensor | FLIR | Link | A thermal camera, it is a thermal measurement instrument and data recorder that adds tremendous value to your sUAS operations and services. | Resolution: 640×512, Range: N/A, Weight: N/A, Compatibility: DJI V2 Matrice 200-series and Matrice 300 | Contact Manufacturer |

| Hadron 640R | Sensor | FLIR | Link | An easy-to-integrate module that pairs a performance-leading 640×512 resolution radiometric Boson® thermal camera with a 64MP visible camera in a single module. | Thermal Imaging Detector: Boson 640×512 pixels, 12µm pitch, USB 3.0, 2-lane MIPI, Temperature Accuracy: ±5°C less, over 0°C to 100°C range. | Contact Manufacturer |

| Altum-PT | Sensor | MicaSense | Link | A 3-in-1 solution for advanced remote sensing and agricultural research. It integrates a high-resolution panchromatic sensor, a new thermal sensor, and five discrete spectral bands. | Resolution: 12 MP, Range: N/A, Weight: N/A, Compatibility: N/A | $15,995 – $19,995 |

| E10T | Sensor | Yuneec | Link | An advanced thermal camera for commercial applications. | Resolution: 320×256 or 640×512, Range: N/A, Weight: N/A, Compatibility: H520 | Contact Manufacturer |

All sensors are not equal.

They vary in their sensitivity, which in turn affects the temperature differences they can identify optically.

They vary in weight which affects which drones they can be integrated on.

Finally, they have APIs that need to be considered if you will integrate the sensor with your drone and your enterprise systems.

Choose wisely, and the rewards are innumerable.

Some top Thermal Imaging Drone Solutions available in the market today

The rapid advancement of drone technology has brought about significant improvements in various professional applications, particularly in the field of thermal imaging.

Today, numerous thermal imaging drone solutions are available in the market, catering to the diverse needs of various industries.

Some of the top thermal imaging drone solutions include:

| Model Name | Type | Manufacturer | Link | Description | Specifications | Price |

|---|---|---|---|---|---|---|

| EVO II Dual 640T | System | Autel Robotics | Link | A drone system with a thermal imaging camera. It is designed for public safety applications, including search and rescue, and fire services. | Resolution: 640×512, Range: 7.5km, Weight: 1174g, Compatibility: N/A | Contact Manufacturer |

| DJI Mavic 2 Enterprise Advanced | System | DJI | Link | A compact drone solution with a high-resolution thermal sensor for critical operations. | Resolution: 640×512 px, Range: 10 km, Weight: 909 g, Compatibility: N/A | Contact Manufacturer |

| SIRAS™ | System | FLIR | Link | An affordable, easy-to-fly, IP54-rated professional drone with an interchangeable payload system for industrial and utilities inspection, firefighting, law enforcement, and search and rescue missions. | Resolution: 640×512, Range: N/A, Weight: 3.1 kg, Compatibility: N/A | Contact Manufacturer |

| ANAFI Thermal | System | Parrot | Link | A drone system with a thermal imager, designed for professionals to easily capture thermal and visual readings. | Resolution: 160×120, Range: 4km, Weight: 315g, Compatibility: N/A | $1,900 |

| H520E | System | Yuneec | Link | A professional drone for commercial use designed for inspection, law enforcement, security, construction, surveying, and mapping applications. | Resolution: N/A, Range: N/A, Weight: N/A, Compatibility: N/A | Contact Manufacturer |

DJI drones, including the DJI Matrice, The DJI Mavic, and others, have been focusing heavily on increasing their capability to integrate infrared cameras and enabling drone thermal imaging.

The result is a large number of standard offerings of drone thermal cameras.

As we mentioned before, not all sensors are equal, though.

For occasional thermal imagery and thermal data collection, it might make sense to put together a simple system yourself.

That said, it is tricky to integrate the more professional systems.

One of the systems above might be a better choice for you because they are more complete and fully integrated.

Finally, you will need a professional partner to help with custom integrations to get the most accurate and reliable solutions.

Which software do you need to manage your Thermal Imaging data?

- Choose the Right Software: To manage your thermal imaging data; you need a software platform to handle the complex radiometric data captured by thermal drone technology. Look for software compatible with the file formats used by your thermal imaging cameras, such as the Streamline App, or consider the FLIR Ignite cloud software.

- Integrate with Your UAV System: Buy a properly integrated thermal drone technology stack, or integrate your own. Whichever combination you choose, ensure seamless operation, so you can visualize every heat signature and pinpoint anomalous signatures without shutting down operations.

- Harness the Power of HD Video: With the higher resolution lens, a high-sensitivity RGB camera, and a high-definition video transmitter/receiver, your drone pilot and drone operator can monitor the thermal operations in real time.

- Utilize the Onboard PC: Many drone solutions have an onboard PC and power distribution system, making it easy to manage and store your thermal imaging data. Some can even do unique analyses using Artificial Intelligence (AI). Leverage these capabilities.

- Comply with Regulations: Use enterprise solutions to track and report compliance.

Of course, the entire technology software stack you choose must be integrated with your chosen drone management software. We won’t cover that here since you can read all about these choices in our Comprehensive Guide to Drone Management Software Solutions.

How can you get started leveraging Thermal Imaging Drones in your business?

Starting with Thermal Imaging in your business can significantly improve your preventive maintenance and overall environmental health. To begin leveraging thermal imaging technology, follow these simple steps:

- Know the regulations that govern compliance for your operations. Review industrial rules and best practice recommendations. Ensure you are familiar with and understand your local and state regulations.

- Identify the right temperature difference and thermal sensitivity you will be required to measure. The combination will determine the required sensor.

- Understand the benefits: Before investing in thermal imaging, it’s crucial to understand its advantages. Thermal sensors on drones allow for a safer, faster, and more efficient way of measuring temperature differences and identifying heat leaks, heat loss, and anomalous operations.

- Choose the right drone thermal imaging technology: Select a system that best suits your business needs. Options include handheld cameras, fixed-mount cameras, or multi-sensor UAV payloads. Companies like Teledyne FLIR and others offer a range of products for diverse applications. Ensure the sensor you use properly covers the temperature range you monitor.

- Train your staff: Once you’ve chosen a suitable thermal imaging system, ensure your employees are adequately trained in its use. This will guarantee maximum efficiency and safety during inspections.

- Implement thermal imaging in your processes: Incorporate handheld and aerial combinations into your routine inspections to improve the speed and accuracy of your inspections, increasing safety for your workforce and reducing the cost of your overall maintenance program.

- Use the results to inform your preventive maintenance program. Follow the regulations for timely repairs you identify above the threshold levels you set for your compliance.

- Monitor and maintain: Continuously track your thermal camera’s performance (they do need to be recalibrated occasionally), keep up with industry standards and regulations, and make adjustments as necessary to ensure ongoing efficiency and effectiveness.

- Roll all of these steps into a proper formal thermal imaging PM process.

Our experience with Professional Thermal Reporting Software for FLIR Cameras

The true value of thermal inspection is turning the images and data into meaningful insights.

Early on we recognized the room for improvement and set out to improve delivery and management of thermal reporting.

We developed a method and tools called Viper View.

Viper View

The software was developed to support images and sequences from almost all FLIR cameras: T10xx Series, T6xx Series, T4xx Series, Exx Series, Ex Series, Cx Series, A3xx Series, A3x5 Series, A6x5 Series, and Ax5 Series.

Viper View Reporting – Made quick work of creating shareable data from the thermal inspection with easier Reporting. Customizable and dynamic templates reduced the risk of errors. Data comparison is easy with plot profiles, histograms, and formula calculations from multiple images.

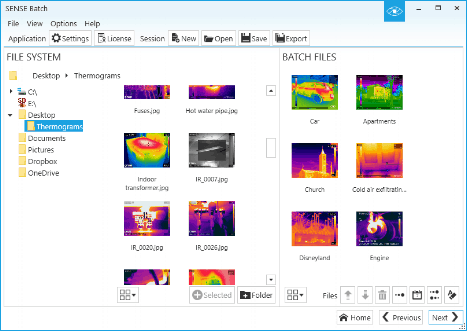

Viper View Batch

We were able to work more efficiently with Viper View Batch thermal images batch processing software and automate a number of tedious tasks; normalize images to use the same temperature unit, apply an isotherm, change palette, or find extreme spots and mark them with measurement tools – all in a matter of seconds.

Viper View Collect

The Viper View camera controller gives you unique remote control of your high-end thermal sensors.

Viper View communicated via radio link without the need for 3/4G or Wi-Fi – an infrastructure-independent solution! The operator could toggle through preset palettes and measurement profiles, set temperature range, and record radiometric data together with the high-resolution visual video.

Developed on the official and latest FLIR SDK , Viper View fully supports post-analysis in FLIR Tools, Tools+, and Research IR.

Sharing the lessons learned

We decided to turn all of our experience with Viper View into lessons learned which we now apply to all offerings.